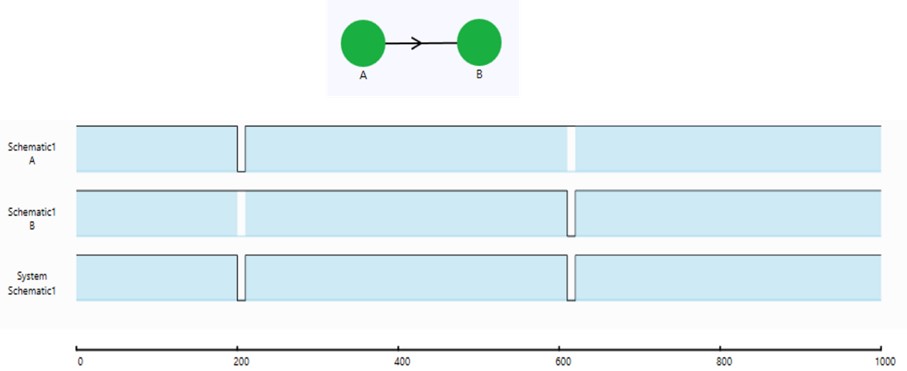

System Availability is a common metric in RAM (Reliability, Availability and Maintainability) analysis. This article provides a brief description of how Availability is calculated, explains its limitations as a reliability metric, and introduces a useful alternative, Efficiency. Consider a system that consists of two equipment (A and B) in series, each has a production rate (flowrate) of 1 unit/hour, such that the ideal output over 1000 hours is 1000 units, for example in figure 1 below.

System Availability is a common metric in Reliability, Availability and Maintainability (RAM) Analysis.

In the above operating profile, the system has a total downtime of 20 hours due to failures of A and B. The system availability is calculated as follow:

Availability (system) = Uptime / Total operating time = (1000-20)/1000 = 0.98

We define Efficiency as the ratio of the total output to the ideal output (if equipment doesn’t fail). Efficiency = 980/1000 = 0.98

For a simple series system, Availability and Efficiency are the same.

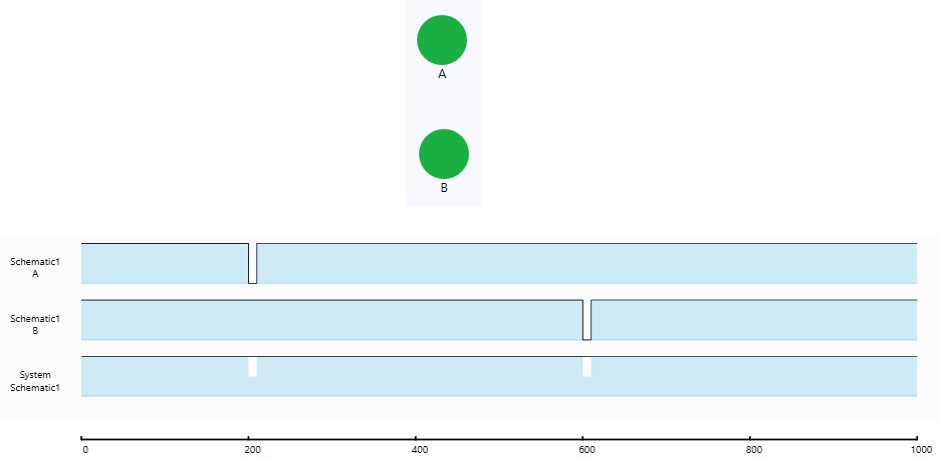

Now, consider a system that consists of two equipment (A and B) in parallel, each has a production rate of 0.5 unit/hour, such that the ideal output over 1000 hours is still 1000 units.

The system total downtime is 0 hours.

Availability (system) = Uptime / Total operating time = 1

The losses due to equipment (A and B) failures = 0.5 x 10 x 2 = 10 units

Efficiency = (1000 – 10) / 1000 = 0.99

The Availability metric gives the impression that the system is perfect, while the Efficiency metric reflexes that there is a 1% loss for the system.

The above examples demonstrate the limitation in using Availability metric to measure the reliability performance of their system. For system that contains equipment in parallel, availability tends to provide an optimistic result that gives the illusion that the system is healthy even if the individual equipment is not healthy reliability-wise.

If the management is concerned about the production (reliability) performance of their system, Efficiency metric should be used, especially when the network consists of equipment operating in redundancy configuration.

With Efficiency metric, manager can anticipate the future loss (while Availability cannot be used for this purpose). Once the projected loss is determined, the analyst would be interested in the list of bad-actors in terms of loss contribution. These are useful information for managers to make decisions related to asset management. In the subsequent series, we will discuss how to determine the loss contributed by individual equipment.

-End-